How to Choose the Right Laser Marking Machine for Your Business?

Selecting the right laser marking machine is a strategic investment that directly impacts production efficiency, marking quality, compliance, and long-term operating costs. We approach this decision with a business-first mindset, evaluating not only technical performance but also scalability, reliability, and return on investment. This comprehensive guide outlines the critical factors that determine whether a laser marking solution truly aligns with your operational goals.

Understanding Laser Marking Technology in Modern Manufacturing

Laser marking is a non-contact, permanent marking process that uses a concentrated laser beam to alter the surface of a material. Unlike ink-based or mechanical methods, laser marking delivers high precision, durability, and consistency, making it ideal for industries that demand traceability, branding, and compliance.

Modern laser marking systems support a wide range of applications, including serial numbers, QR codes, barcodes, logos, batch codes, and regulatory markings. The technology integrates seamlessly into automated production lines, ensuring speed without sacrificing accuracy.

Evaluate Your Material Compatibility Requirements

Material type is the most decisive factor when choosing a laser marking machine. Different materials respond differently to specific laser wavelengths and power levels.

Metal Marking Applications

For metals such as stainless steel, aluminum, brass, copper, and titanium, fiber laser marking machines provide exceptional contrast, deep engraving capability, and long service life. They are widely used in automotive, aerospace, medical devices, and electronics manufacturing.

Plastic and Organic Materials

Plastics, rubber, leather, wood, and coated materials often require controlled heat input to avoid deformation or discoloration. CO₂ laser marking machines are optimized for these substrates, delivering clean, high-speed marks with minimal thermal stress.

Sensitive and High-Precision Materials

For applications involving glass, ceramics, silicon wafers, or microelectronics, UV laser marking machines offer ultra-fine resolution and cold marking, ensuring zero damage to delicate surfaces.

Choose the Appropriate Laser Source Type

Selecting the correct laser source ensures optimal marking results and cost efficiency.

Fiber Laser Marking Machines

Fiber lasers are the industry standard for metal marking. They offer:

High electro-optical efficiency

Minimal maintenance

Long operational lifespan

Excellent beam quality for fine details

These systems are ideal for high-volume production environments requiring speed and durability.

CO₂ Laser Marking Machines

CO₂ lasers excel in marking non-metallic materials. They are commonly used in:

Packaging

Signage

Consumer goods

Textile and woodworking industries

Their versatility and lower upfront cost make them attractive for diverse applications.

UV Laser Marking Machines

UV lasers deliver unmatched precision. They are preferred when:

Micro-marking is required

Heat-sensitive materials are involved

High-contrast, cosmetic-quality marks are essential

Define Marking Depth, Speed, and Resolution Needs

We always align machine specifications with actual production requirements.

Marking depth determines durability, especially for parts exposed to abrasion or harsh environments.

Marking speed impacts throughput and production efficiency.

Resolution and spot size influence clarity for small text, logos, and data matrix codes.

Balancing these parameters ensures the system meets both current production demands and future growth.

Assess Power Output and Performance Stability

Laser power directly affects marking speed and depth. Low-power systems are suitable for surface marking, while higher power levels enable deep engraving and faster cycle times. However, excessive power can compromise surface quality on certain materials.

Equally important is power stability. Consistent output ensures uniform marking across batches, reducing rejects and rework.

Consider Automation and Integration Capabilities

Modern manufacturing environments demand seamless integration. A reliable laser marking machine should support:

PLC and MES system connectivity

Robotic arm integration

Conveyor-based automation

Vision systems for alignment and inspection

Automation-ready machines reduce labor costs, minimize human error, and support Industry 4.0 initiatives.

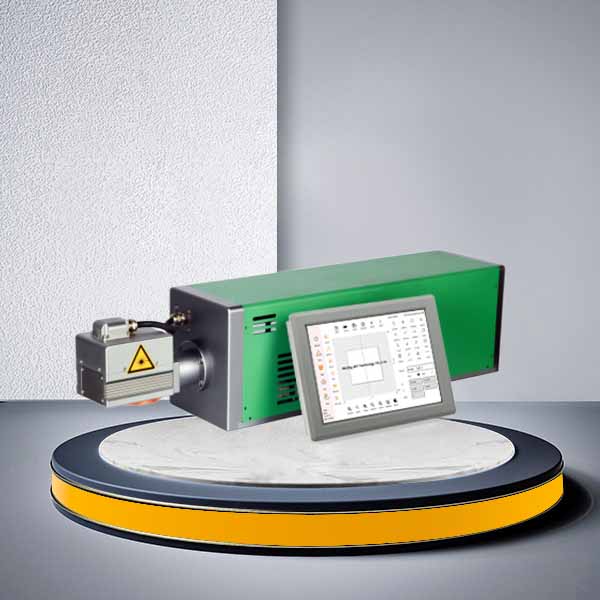

Software Functionality and User Experience

Advanced software transforms a laser marking machine into a productivity tool. We prioritize systems with:

Intuitive user interfaces

Support for vector files, barcodes, and serial databases

Real-time parameter adjustment

Multi-language operation

Powerful software enables rapid job changes, efficient batch processing, and precise control over marking quality.

Maintenance, Reliability, and Total Cost of Ownership

Initial purchase price is only part of the investment. We evaluate the total cost of ownership, including:

Energy consumption

Consumables

Maintenance intervals

Downtime risk

Laser marking machines with sealed laser sources, air-cooled designs, and modular components significantly reduce operating costs over time.

Safety, Compliance, and Environmental Considerations

Compliance with international safety standards is non-negotiable. A professional laser marking solution should include:

Protective enclosures

Fume extraction systems

Emergency stop mechanisms

Laser safety certifications

Environmentally, laser marking is a clean and sustainable process, eliminating inks, chemicals, and consumables.

Scalability and Future-Proof Investment

Business needs evolve. We select laser marking machines that can scale with:

Increased production volumes

New materials

Advanced automation upgrades

A future-proof system protects capital investment while enabling long-term competitiveness.

Industry-Specific Use Cases and Customization

Different industries demand tailored solutions:

Medical devices require permanent, biocompatible markings

Automotive parts demand high-speed traceability codes

Electronics need micro-scale precision

Packaging focuses on speed and flexibility

Customization options such as rotary fixtures, 3D marking, and multi-axis control further enhance versatility.

Making the Final Decision with Confidence

Choosing the right laser marking machine is a strategic decision that affects product quality, operational efficiency, and brand reputation. By carefully evaluating materials, laser type, power, automation readiness, software capability, and long-term costs, we ensure a solution that delivers consistent performance and measurable value.

For more details please contact Beijing JCZ